Keiser University Press Box

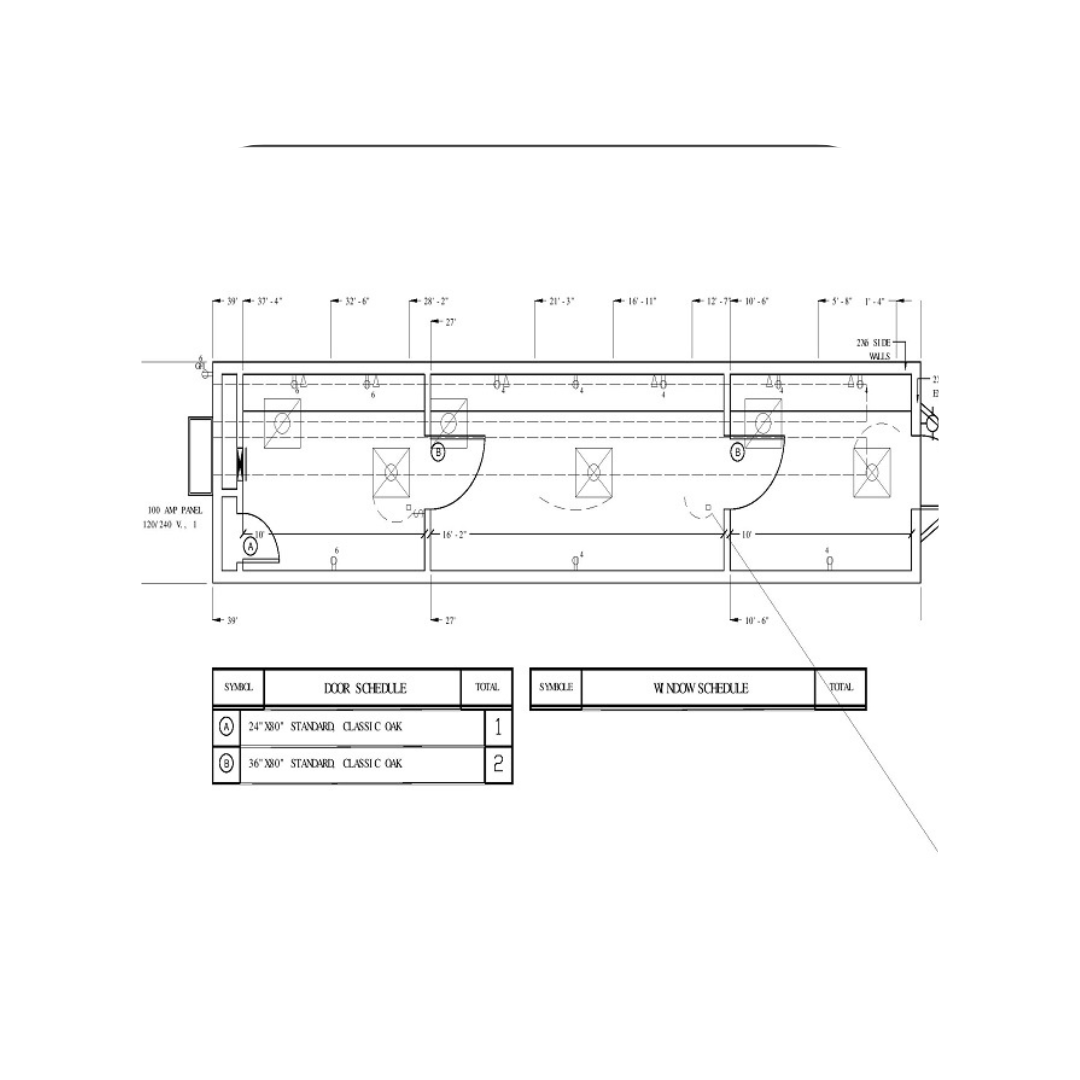

Keiser University needed a press box for their new football program. Their football field will be relocated within two years, so a modular relocatable press box was a natural fit for this project. The 9’ x 39’ building was designed with three rooms to accommodate home team coaches, visiting team coaches, and game announcers. The building features large, impact-resistant viewing windows and a rooftop platform for photographers and videographers.

The building is situated alongside the university’s football field at the 50-yard line and was installed atop 10’ site-built concrete pilings, providing an excellent view of the action on the field.

The exterior was designed with Hardie Panel stucco embossed to match the adjacent athletic building. The interior was designed for durability and ease of maintenance, using vinyl covered gypsum and vinyl block tile.

Keiser University Press Box

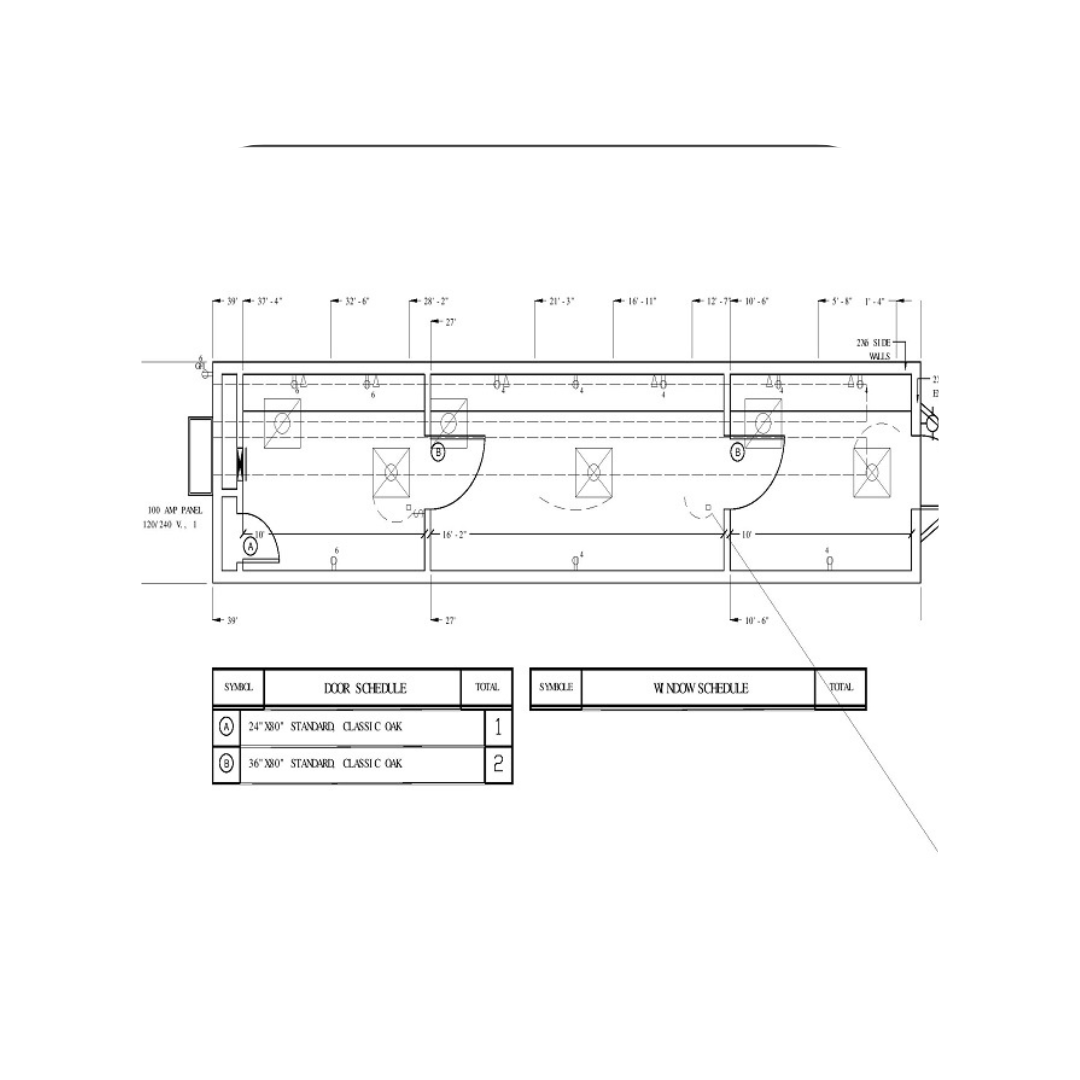

Keiser University needed a press box for their new football program. Their football field will be relocated within two years, so a modular relocatable press box was a natural fit for this project. The 9’ x 39’ building was designed with three rooms to accommodate home team coaches, visiting team coaches, and game announcers. The building features large, impact-resistant viewing windows and a rooftop platform for photographers and videographers.

The building is situated alongside the university’s football field at the 50-yard line and was installed atop 10’ site-built concrete pilings, providing an excellent view of the action on the field.

The exterior was designed with Hardie Panel stucco embossed to match the adjacent athletic building. The interior was designed for durability and ease of maintenance, using vinyl covered gypsum and vinyl block tile.

Relocatable Modular Special Application under 10,000 sq. ft.

Technical Innovation & Sustainability

Advanced Modular Structures Inc. contracted with Diamond Builders Inc. to construct the press box off-site, based on our design and stringent site-plan covenants. The building was designed and built for High Velocity Hurricane Zone, with the ability to withstand 170mph winds per Florida Building Code.

Impact doors and windows were installed to eliminate the need for hurricane shutters. The roof trusses were custom designed to support the weight of occupants and to support the aluminum roof-rails. The rooftop viewing deck live load capacity is 5,000 lbs.

A steel perimeter frame and galvanized bottom board were installed so the building could be welded to the site-built concrete pilings. High PSI early-strength concrete was used for the foundation and pilings to accommodate the project’s time

Cost Effectiveness

The modular press box building, custom decks and steps were all constructed completely off-site, allowing site work and manufacturing to proceed concurrently. Lift rings were installed on the building, so it can be relocated by crane in the future.

The foundation was poured as a mat-type foundation rather than a piling foundation, saving the customer thousands of dollars. After delivery to the site, the rails, steps and decks were installed, and the building was crane set onto the pilings and welded into place. Installation was completed in one day, and a special inspector for the foundation, welding and bolt connection was used to expedite the inspection process.

The speed of the construction and installation process ensured that the press box was complete in time for the football team’s first home game.

Project Details:

Affiliate: Diamond Builder

Location: West Palm Beach, Florida

Building Use: Press Box for Football Team

Number of Modules: 1

Total Square Feet: 351

Days to Complete: 37

Looking to learn more?

Contact Diamond Builders Today: